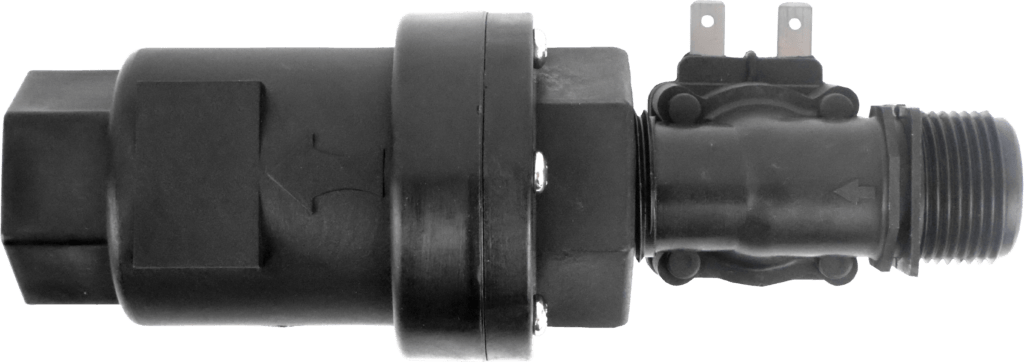

The solenoid is a wearing part and will eventually need to be replaced. Over time, the diaphragm inside the solenoid may deteriorate, which will cause the water to flow continuously.

If the diaphragm splits, it could be caused by high pressure in the line. Install a pressure limiting valve on the water supply line if the onsite pressure is greater than 116 PSI / 800kPa.

Failure to open

1. Incorrect installation of solenoid

NOTE: This section only applies to new installations, and only for the solenoid which is provided with the Water Witch.

If the solenoid and/or backflow prevention valve have been installed incorrectly, water will not be added into the pool or tank. This will occur if the arrows do not point in the direction of water flow.

2. No water source

- If the installation’s fill line has been plumbed into the mains supply, check that the mains shutoff valve is open.

- Set the tap or two-way valve to the open position.

- Observe whether water is flowing into the pool or tank.

NOTE: It may be more difficult to see whether water is flowing if the solenoid was installed into the filtration return line. It is recommended to turn off the pump and listen for running water.

3. Low pressure in fill line

The solenoid will not open if the fill line pressure is below 29 PSI / 200kPa.

Confirm that the pressure in the line is within the operating range of 29 to 116 PSI (200 – 800kPa).

NOTE: It is important to consider the impact of other taps or irrigation systems at your property which may hinder the performance of the device. If multiple taps are turned on the water pressure in the Water Witch supply line may be reduced to below the minimum requirement.

4. Damaged solenoid or cable

A damaged or worn solenoid or cable will often trigger a Fault 4. Replace as necessary.

See Replacing a solenoid.

Failure to close

If the water is not shutting off and your control box is reading SCAN, then the solenoid may need to be replaced.

See Replacing a solenoid.

Checking the cable

If there is a cable issue, it can affect the control box’s functionality and prevent the solenoid from actuating.

1. Loose connection

Over time, the cable may come loose at either end.

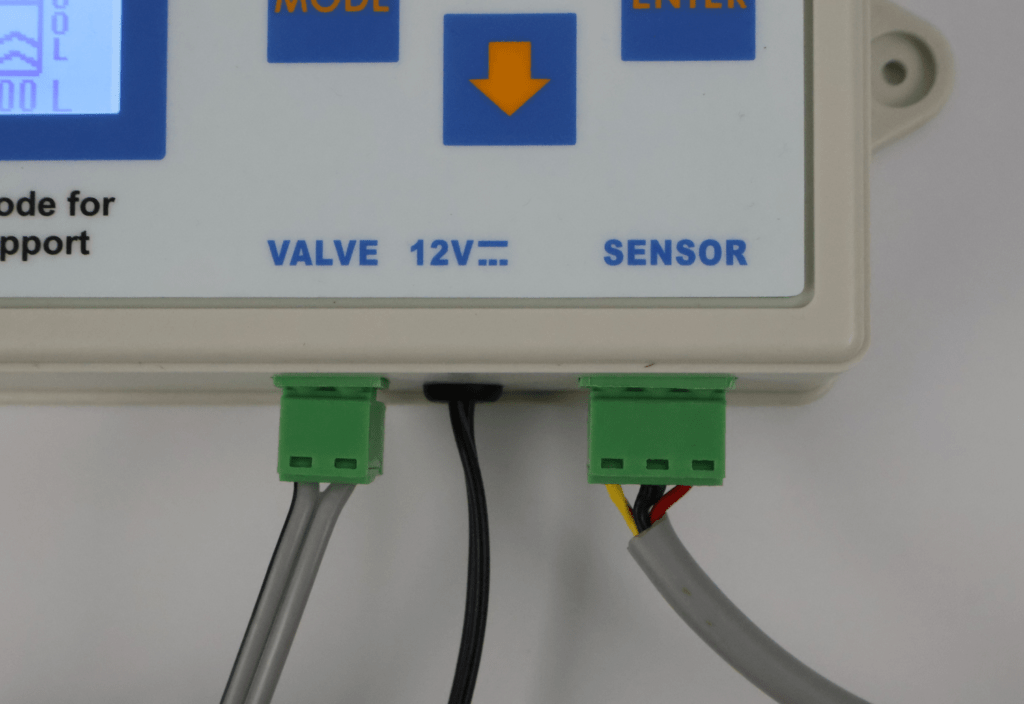

Check that the green plug on the underside of the control box is inserted correctly and the individual wires are connected correctly to the plug.

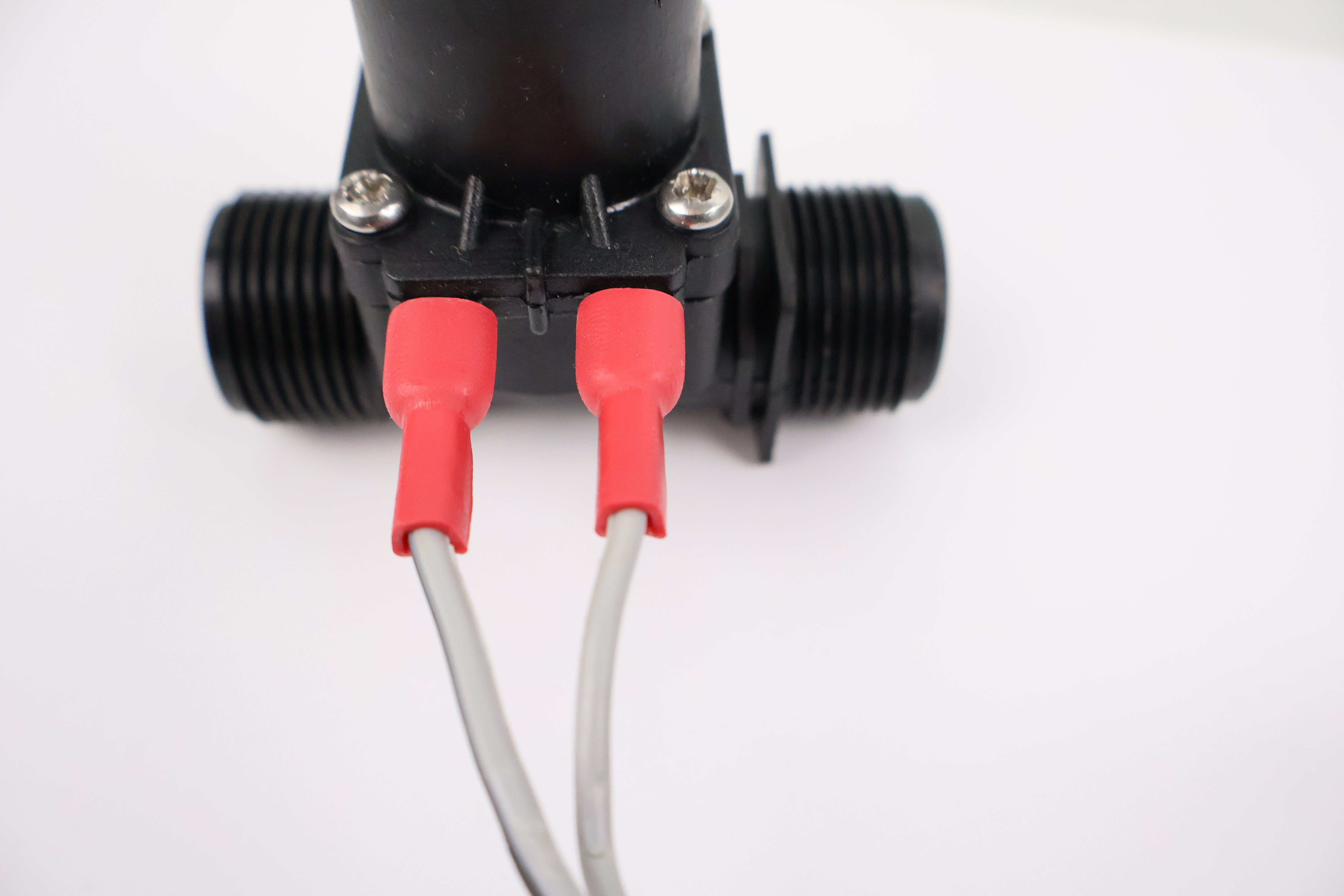

Observe that the red connectors are firmly attached to the solenoid pins.

If there is a fault on the control box, press ENTER to clear it.

Monitor the operation of the Water Witch for any further issues.

2. Damaged cable

If the cable is frayed or cut, it will not allow for signal transfer between the solenoid and the control box, which can trigger either Fault 3 or Fault 4.

Inspect the cable for damage and replace if necessary.